Have you heard about the industrial revolution 4.0? Well, It is a new production culture based on automated interaction, which takes place between a system and a device. The goal is to increase the efficiency of processes, reducing risks to employees and costs for the company. This scenario was only possible thanks to technologies such as the Internet of Things, cloud computing, Machine Learning and artificial intelligence.

The goal is to promote the automation of all industrial production, focusing on increasing efficiency. In this scenario, all devices, machines, sensors, tools, and parts will be able to exchange data with each other and with the web and gather the information into a centralized database. In this way, all movements are mapped and the collected data can be used as the basis for a more solid management.

In this post, we aim to help you understand what industrial revolution 4.0 is; analyzing its characteristics, importance and main challenges for companies to reach this level. Check it out!

What are the main characteristics of the industrial revolution 4.0?

Read below to find out what the main characteristics of this revolution are and how they relate to the technologies that give the foundation to industrial revolution 4.0.

Flexible production line

Production line tasks can be modified quickly with the process called modularity. The automatic coupling and decoupling of different modules allows the company to manufacture different products in sequences, without the need to reconfigure the entire process.

Thus, production is not limited and can be optimized according to demand, besides enabling the customization of products. All this is possible thanks to the combination of two technologies that are pillars of industrial revolution 4.0; the Internet of Things and artificial intelligence.

Decentralized work

In the scenario of industrial revolution 4.0, the machine is not dependent on the human factor to operate it. It will be controlled by intelligent algorithms, which will command production in real time, producing data about the process so that the manager can get reports whenever he/she thinks it is necessary.

Real-time data capture and analysis

With the use of artificial intelligence, taking advantage of machine learning and the volume of information that Big Data delivers to us, stored data is automatically structured according to the needs of the company.

Thus, insights are produced in an automated way, because the algorithm will learn on its own what it should analyze and the results it needs to deliver. The culmination of this moment is the development of Data Driven Culture.

Considerable advances in virtualization

Cloud computing has defeated virtualization of virtually all of an enterprise’s IT infrastructure. All the processes we mentioned earlier can run on a remote server, contributing to scalability, cost reduction, mobility and increased efficiency.

To run robust algorithms, you need to have a huge computational capacity, which can be acquired directly from a cloud provider to store large volumes of data which can grow or decrease on demand, and are structured and transformed into insights. The company will have to rely on elastic storage, which can be easily found using the cloud.

What is the importance of this revolution in the industrial sector?

The positive impacts of the industrial revolution 4.0 begin with the health and safety benefits of employees. Many functions that were considered risky, today are already performed by intelligent robots, reducing the rate of accidents or ergonomic injuries by repetitive activities.

Integrated logistics

Integration in inventory management will streamline the entire process and dramatically reduce the risk of errors. All processes will be executed efficiently, from manufacturing to delivery, through the entry and exit of goods from the system.

Smart software identifies stranded goods and sales-defending products by generating reports that will have a direct impact on purchases. There is the possibility of automatic notification to suppliers, warning in advance to send the goods that are missing. Even the purchase of raw material can be controlled automatically.

Efficiency in decision-making

In terms of management, the gains that will come with intelligent real-time data production, structuring and custom reporting will allow for problem correction before they become a snowball. Decision-making will be much more grounded and accurate, based on solid data and no longer on feelings.

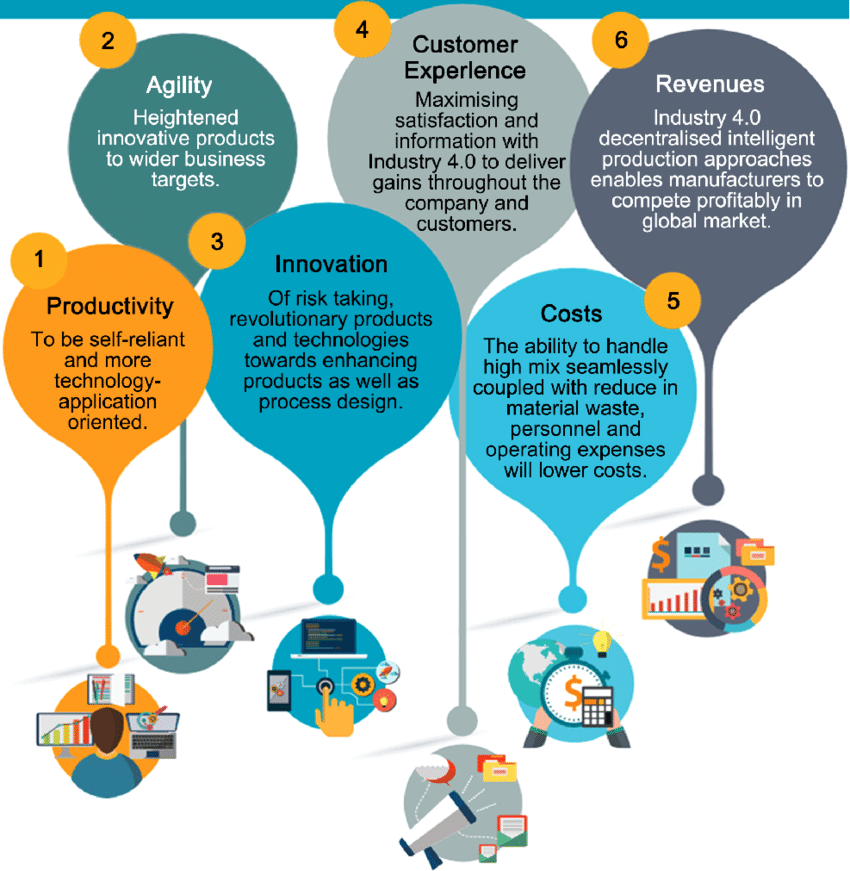

With all these changes, we will have a revolution in the growth of the market, which will respond with much more agility to the movements, guided by customized solutions and increasingly aligned with the customer and the needs of their time. Those who do not adapt to the industrial revolution 4.0 will undoubtedly have a short life.

What are the biggest challenges of industrial revolution 4.0?

In this topic, we will focus on the challenges that Brazil has in relation to the industrial revolution 4.0, because unfortunately, we still have to overcome many barriers to consolidate ourselves in such a process. Among these barriers, we can highlight the lack of structure and skilled labor. See below what our main challenges are in this new scenario:

Technological development

There is no escape, to reach a level of success in the industrial revolution 4.0, we need more investments and technological development projects. This is a big challenge for companies, but it should also be a concern of the government, which should generate the necessary incentives to start this move. It is important to identify the sectors where barriers are smaller and have the greatest development potential.

Telecommunications infrastructure

Although we have seen advances in recent years, Brazil is far from a reference when it comes to telecommunications infrastructure for high-performance activities. The flow of information that is generated and transported in this industry model requires speed and stability. Once again, companies and government must work in partnership and find solutions to this bottleneck.

Professional training

The industrial revolution has come to change the productive paradigm and requires professionals to be prepared for it. We are not only talking about cultural change, or mindset, but of the qualification to deal with all new technologies being adopted, such as artificial intelligence, process robotization, data mining, development, among others.

Currently, we already have a deficit of IT professionals to fill the current vacancies in the country, with a much higher demand than supply.

To get an idea, today, in the country there are approximately 13 million unemployed, and it is estimated that by 2022 the IT market will need more than 750,000 professionals in Brazil – vacancies that have no prospect of being filled. It is a structural issue that needs correction from both the private sector and the government, with incentives.

Leadership development

Current leaders, if they want to stay in office and earn their company returns, should be open-minded to this new model. They must first go through the process of changing organizational culture, with a breaking of paradigms, and then transmit it.

We hope that after reading this post, you have understood how the industrial revolution 4.0 will change the paradigm of world production through digital transformation.

We have several challenges to make Brazil reach this level, many companies are ready to deal with this moment, providing consultancy and offering solutions so that this immersion is as smooth as possible. Having a qualified partner who delivers the right tools can be the first step for your company to successfully immerse itself in the industrial revolution 4.0.

Did you enjoy the post and its information? Then subscribe now to our newsletter and receive our news firsthand.